P. Cavaliere, A. Perrone, A. Silvello, A. Laska, G. Blasi and I. Garcia Cano https://doi.org/10.3390/met12050780

Abstract:

Cold-spray coatings were produced by FeCoCrNiMn high-entropy alloy powders deposited

on carbon steel substrate. The coatings were realized at intermediate temperature and high

pressure (at 1100 °C and 7 MPa). The coating microstructure was characterized by scanning electron

microscopy and X-ray diffraction, revealing a very dense deposition and high flattening ratio of the

splatted particles. This had a large influence on the strong adhesion of the coating to the substrate.

The hardness and residual stress profiles were measured through nanoindentation and X-ray diffraction

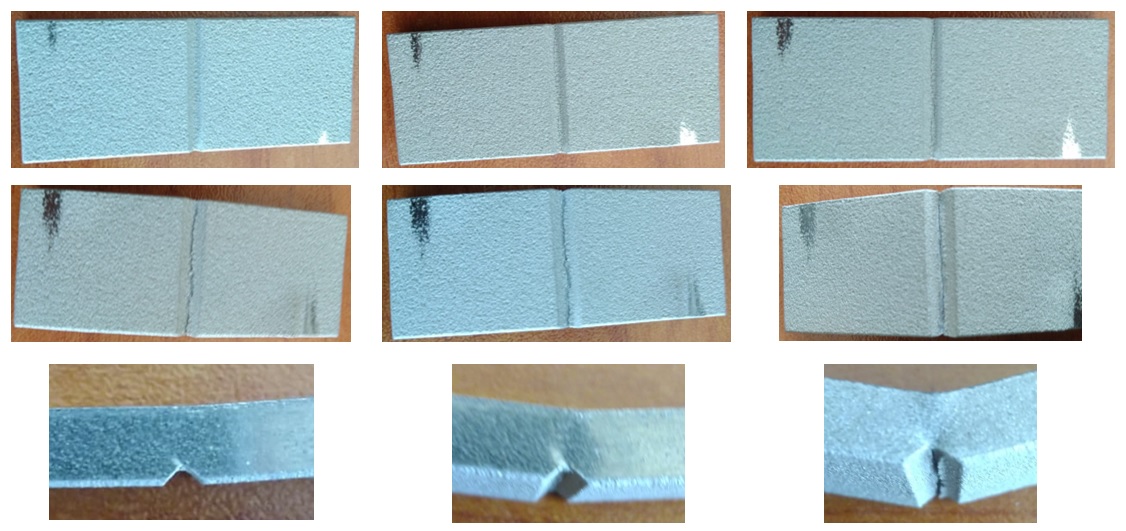

from the peak broadening measured layer by layer. The cyclic behavior of the coatings was

evaluated through three-point bending tests performed on V-notched samples coated via cold

spray. Cyclic tests were performed at different maximum strokes from 0.3 to 3.6 mm in order to

monitor the crack initiation and propagation during bending tests. The fracture surface aspect was

analyzed by scanning electron microscopy in order to reveal the fracture mechanisms in different

deformation conditions.

Keywords: high-entropy alloy; cold spray; residual stresses; V-notch; cyclic bending; fracture surface