Vaz, R.F.; Silvello, A.; Sanchez, J.; Albaladejo, A.; García-Cano, I. (2021). The Influence of the Powder Characteristics on 316L Stainless Steel Coatings Sprayed by Cold Gas Spray. Coatings, Vol. 11, Nº 2, Article nº 168. Doi: https://doi.org/10.3390/coatings11020168 Open access link: https://www.mdpi.com/2079-6412/11/2/168/htm

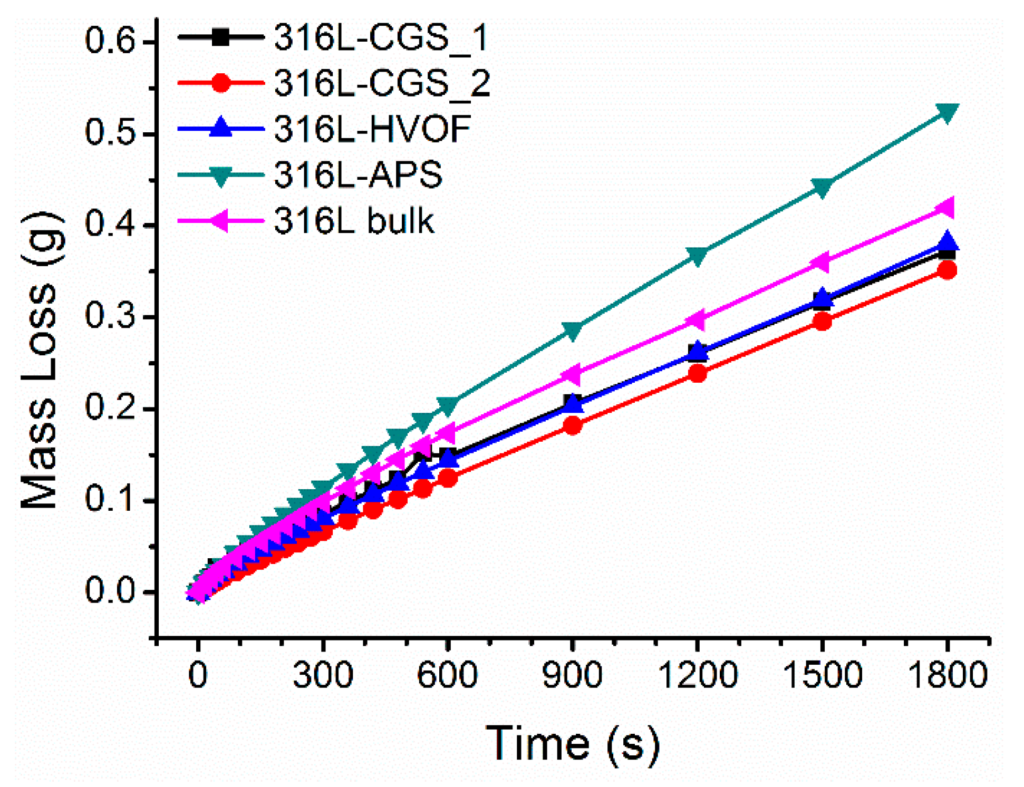

Abstract: Thermally sprayed 316L stainless steel coatings are commonly used on metallic structures due to their corrosion and wear resistance when compared to carbon steel. Cold Gas Spray (CGS) is a convenient thermal spray process to deposit 316L coatings, producing thick and very dense coatings, with almost no deleterious changes on the feedstock properties to the coating condition. The powder characteristics have influence on the microstructure of the coating, such as porosity and oxide contents, which alter its corrosion and wear behavior. CGS is an efficient technique to reduce the problems associated with material melting commonly found in other conventional thermal spray methods. In this work, different 316L powders, produced by different manufacturers, were deposited by CGS, applying the same equipment and parameters, with the objective to evaluate the relation between the powders’ characteristics and coating properties. Their microstructure, adherence, hardness, as well as the performance on corrosion and wear testing were evaluated. The water atomized powders presented in general better results than gas atomized powders.

Keywords: 316L; cold gas spray; powder shape; corrosion; wear