Bulnes, A.G.; Albaladejo-Fuentes, V.; Cano, I.G.; Dosta, S. (2020). Understanding the Influence of High Velocity Thermal Spray Techniques on the Properties of Different Anti-Wear WC-Based Coatings. Coatings, Vol. 10, Nº 12, Article nº 1157. Doi: 10.3390/coatings10121157 Link: https://www.mdpi.com/2079-6412/10/12/1157

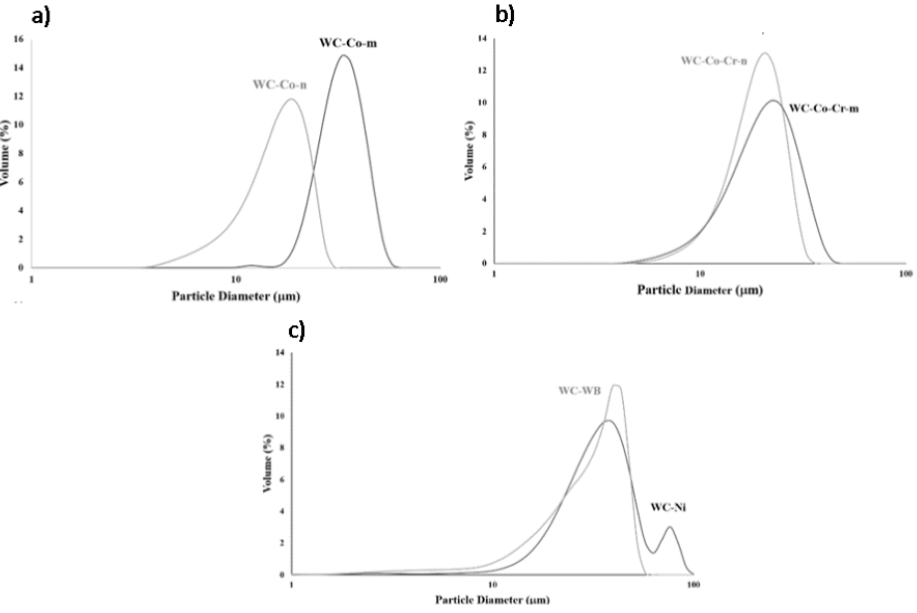

Abstract: This work analyzes the differences found in hard metal coatings produced by two high velocity thermal spray techniques, namely high velocity oxy-fuel (HVOF) and high velocity air-fuel (HVAF). Additionally, the effect of the metallic matrix and ceramic composition and the original carbide grain size on coating properties is compared to the most studied standard reference material sprayed by HVOF, WC-Co. For this evaluation, the physical properties of the coatings, including feedstock characteristics, porosity, thickness, roughness, hardness, and phase composition were investigated. Several characterization methods were used for this purpose: optical microscopy (OM), scanning electronic microscopy (SEM), Energy-dispersive X-ray spectroscopy (EDS), and X-ray Diffraction (XRD), among others. The final performance (abrasive wear and corrosion resistance) shown by the coatings obtained by these two methodologies was also analyzed. Thus, the abrasive wear resistance was analyzed by the rubber-wheel test, while the corrosion resistance was characterized with electrochemical methods. The characterization results obtained clearly showed that the coatings exhibit different microstructures according to feedstock powder characteristics (carbide grain size and/or composition) and the thermal spray process used for its deposition. Thus, the incorporation of WB to the cermet composition led to a high hardness coating, and the complementary hardness and toughness of the WC-Co coatings justify its better abrasion resistance. The presence of Ni on the metal matrix increases the free corrosion potential of the coating to more noble region. However, the WC-Co coatings show a lower corrosion rate and hence a higher protective performance than the rest of the coatings.

Keywords: Thermal spray; HVAF; HVOF; WC-based coatings; cermet materials; wear resistance;

The content of this article is a result from FAMPAI Project (COMRDI16-1-0020-02) cofounded by the European Regional Development Fund (FEDER) under the FEDER Catalonia Operative Programme 2014-2020.