Microstructural, Mechanical and Wear Properties of Atmospheric Plasma-Sprayed and High-Velocity Oxy-Fuel AlCoCrFeNi Equiatomic High-Entropy Alloys (HEAs) Coatings

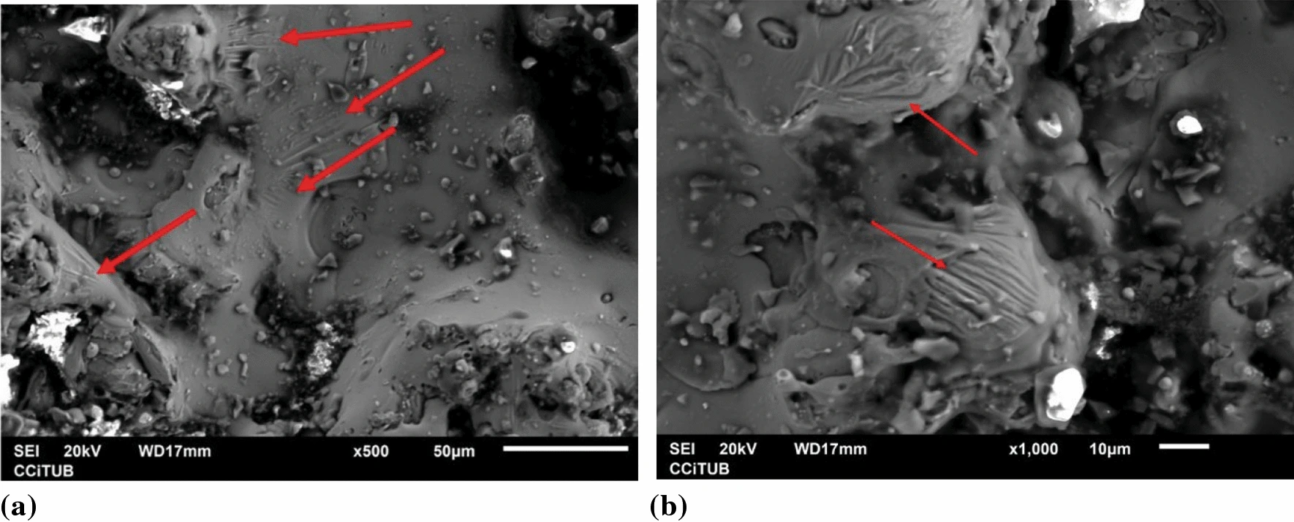

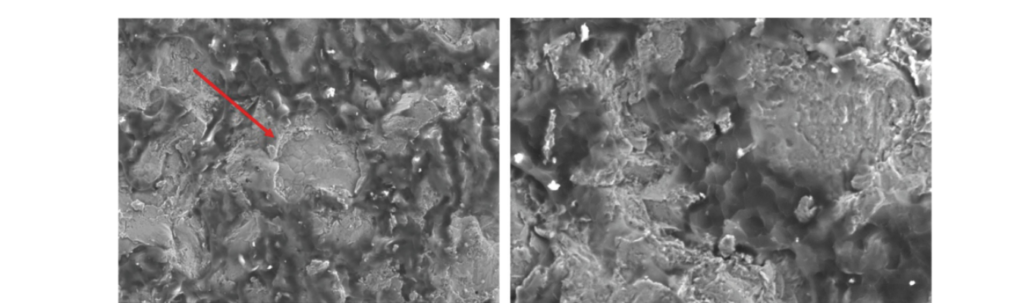

In this investigation, atmospheric plasma spray (APS) and high-velocity oxy-fuel (HVOF) techniques were used to produce AlCoCrFeNi coatings. High-entropy alloys (HEAs), due to their mechanical, chemical, and physical properties are capturing the attention of the international scientific community. Starting feedstock powders were characterized in terms of size, phase, and size, and corrosion test in NaCl, ball on disk, rubber wheel, and jet erosion tests was carried out on the obtained coatings. The results of the tribological investigation show that in the case of APS coatings, corrosion and wear behavior depend on the microstructure phases of the coating, as well as the amount of oxides. In particular, the wear morphology of APS surfaces is characterized by brittle fracture, with the presence of pores, cracks, and grooves. For HVOF coatings, further investigations on process parameters are needed because of the poor adhesion strength between the coating and the substrate. Anyway, the obtained corrosion resistance of HVOF coating is greater than that of the C steel substrate used to benchmark the results, and in addition, it ensures better performances in rubber wheel and jet erosion tests, but its wear resistance in the ball-on-disk test is worse because of the debris remaining in the wear track.

View Full-Text: https://link.springer.com/article/10.1007/s11666-022-01520-y